-

Shipping/Export Information

Animal Feed Supplement (Aquatic, poultry and cattle)

HS Code 2303

Packaging: Packed in 50kg BOPP bags.

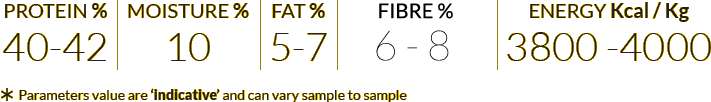

IFB Newgen DDGS™ has great potential value to lower cost in various animal feed rations. It has various benefits.

- Single feed raw material—broken rice; low anti-nutritional factors.

- Phytic acid control in our IFB Newgen DDGS increases digestibility.

- Distillery process is free from the use of sulfuric acid, which makes the product inorganic sulphur free and eliminates chances of nutritional problems in ruminant diets.

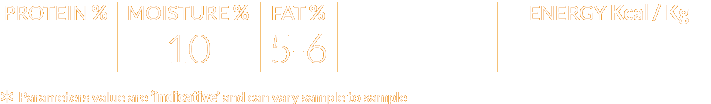

IFB Feedstar™—value added nutrients for cattle, fish and swine feed, it has various benefits

- Fermentation contributes 3-5% dried yeast cells to Feedstar, which provides Vitamin B complex, promotes palatability and increases feed consumption.

- The phosphorus present in Feedstar lowers the requirement of addition of di-calcium phosphate and thus reduces cost.

- Contains 5–6% fat which is an excellent source of linoleic acid and energy.

-

Superior Feed Supplement

The installation of a state-of-the-art low temperature fluidised bed dryer, together with PLC control, preserves all nutritional values in the final rice-based IFB Newgen DDGS™ products.

Leading edge technology

- Asia’s first DDGS plant with unique fluidised bed drying system. Fully automated drying plant with less manual intervention.

- Drying bed temperature is precisely controlled by PLC and always maintained below 70°C to avoid burning/denaturing of the DDGS/protein.

- Owing to low temperature drying, the Acid Detergent Insoluble Nitrogen (ADIN) of IFB Newgen DDGS™ is always lower (0.7%) compared to that of other drying technologies, which signifies higher digestibility.

- IFB Newgen DDGS™ always contains higher digestible protein in comparison with any other drying technology.

Soya Meal Vs IFB Newgen DDGS™

-

By-product of the soya bean oil industry

By-product of the grain based alcohol industry, made with advanced technology

-

Exposed to high temperature 105ºC, which will result in deterioration of and other nutritional content protein

Exposed to 70°C maximum temperature—the IFB Newgen DDGS production keeps nutritional value consistent

-

Does not contain pro-biotic nutritional factors

Contains pro-biotic nutritional factors, created during fermentation

-

Exposed and chemical solvents such as Hexene during oil extraction

Not exposed to harmful chemicals during processing

-

Contains anti-nutritional factors such as Trypsin

Does not contain any major anti-nutritional factors